Wicketed Poly Mailers

Wicketed poly mailers are poly mailers put together by a metal wire which is generally called wicket. They are designed to make packaging process for clothing or logistics more time-efficient.

Same as regular poly mailers, wicketed poly mailers have width, height and flap. What makes wicketed possible is by adding a wicket part plus a perforation line on top of the regular flap.

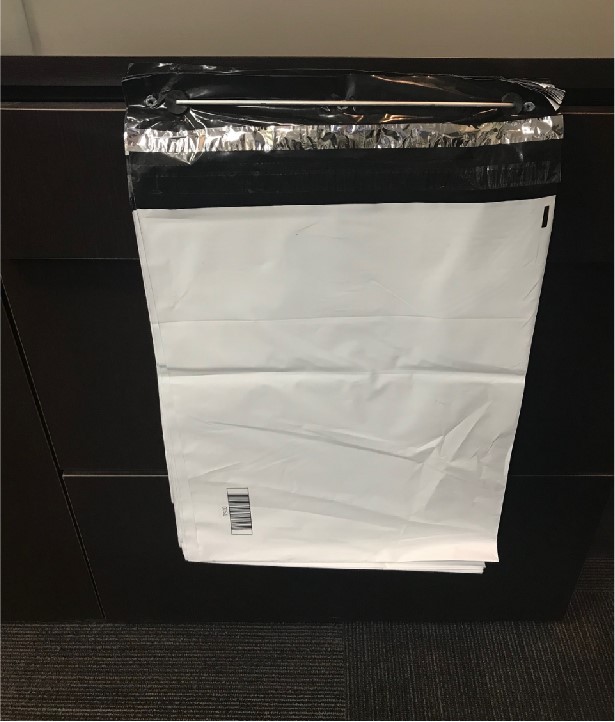

This is what they look like.

What Makes a Wicket?

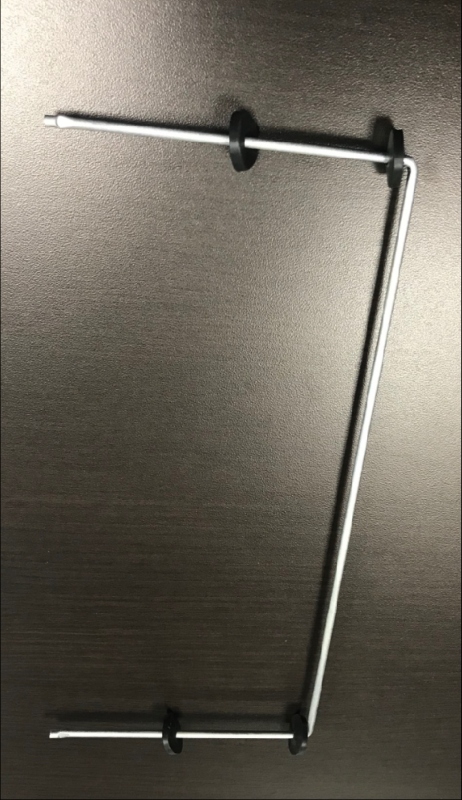

Wickets are consisted of more than a metal wire. Below are a whole set of accessories needed for it.

Four cushioning pads plus a metal wire.

Structure of Wicketed Poly Mailers

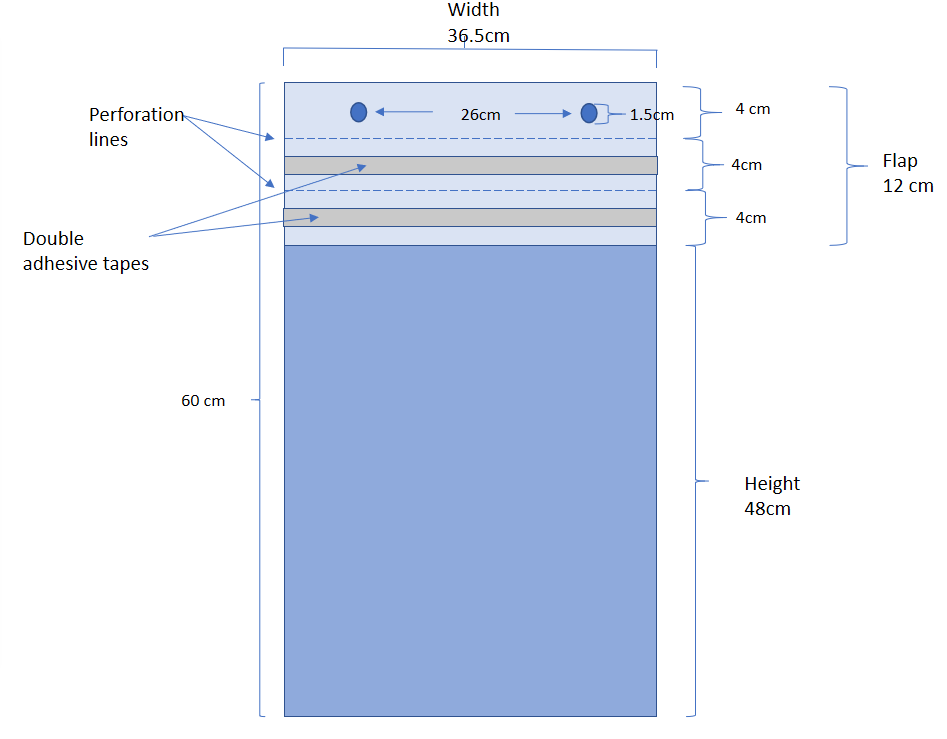

Below is a picture of wicketed poly mailers’ general structure.

We will explain from top down.

On top, we can see two holes. Wickets are inserted by these two holes. In between the two holes, there will be a customized distance. This varies from different width of a poly mailer. It cannot be too long or too short since this will decide if you can do the perforation here faster or not. You can take the distance on above picture as a reference. This is a verified acceptable distance for the wicket. You can use other distance for other poly mailers using same proportion as above.

Under two holes, there is a perforation line. This perforation line cannot be too easy to be torn since the poly mailers will need to be held by the wicket for a while before all the poly mailers on a wicket are used. Before then, this perforation line cannot break automatically.

Till here, it is all about the wicket part for a wicketed poly mailer. General height you can leave for this wicket part can be 4 cm.

It’s always good for us to have more product developments to make our work and life more time and cost-efficient.

So, what do you think of wicketed poly mailers?

ZKK China Company Limited

ZKK China Company Limited